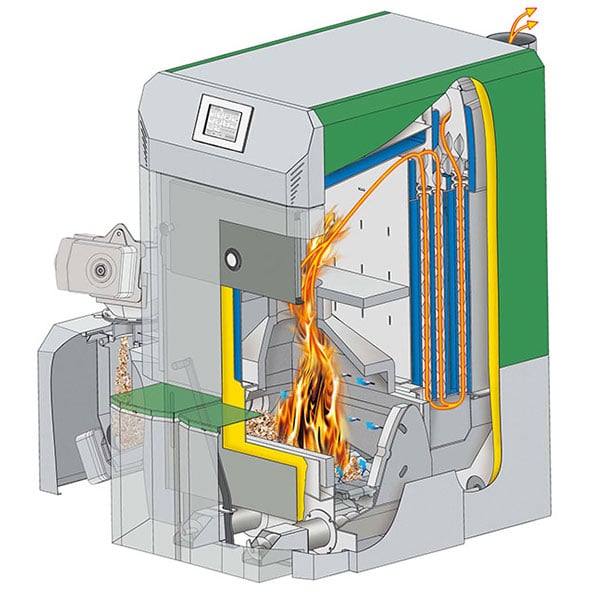

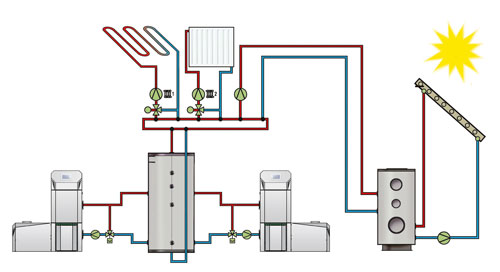

The HERZ firematic 80-301 kW is a biomass boiler for wood chips and wood pellets. Compact, high efficient and economical.

The great advantages of HERZ firematic 80-301 kW

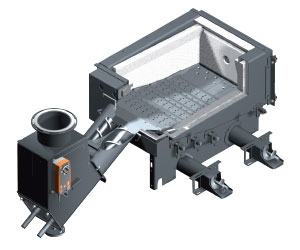

- Wood chips or wood pellets are transported from the side into the combustion chamber (with single stoker screw for firematic 20-101 and double stoker screw for firematic 130-301).

- The movement of the step grate is also a cleaning mechanism of the burning chamber. These grate elements consist of special, highquality cast iron. Through the movement of the step- /moving grid the biomass is transported through the combustion area.

- The cleaning of the combustion chamber from burning ash is carried by an automatically tipping grid. A subjacent mounted ash screw transports the ash directly into the ash container.

- Minimizes the manual cleaning requirement.

- The heat exchanger surface gets cleaned automatically via the integrated turbulators, even during heating operation, no manual cleaning necessary.

- A consistently high level of efficiency thanks to cleaned heat exchanger surfaces enables low fuel consumption.

- The fly ash is taken into the front ash container via a discharge screw.

- A built in lambda probe, which monitors continuously the flue gas content values, detects fuel quality changes and ensures optimum combustion and low emission values.

- The Lambda probe controls the primary and secondary air supply ensuring complete combustion, even in partial load operation.

- The results are low fuel consumption and the lowest emission values even with different fuel qualities.

- Due to the compact design the insertion and assembly can be done very fast & easy.