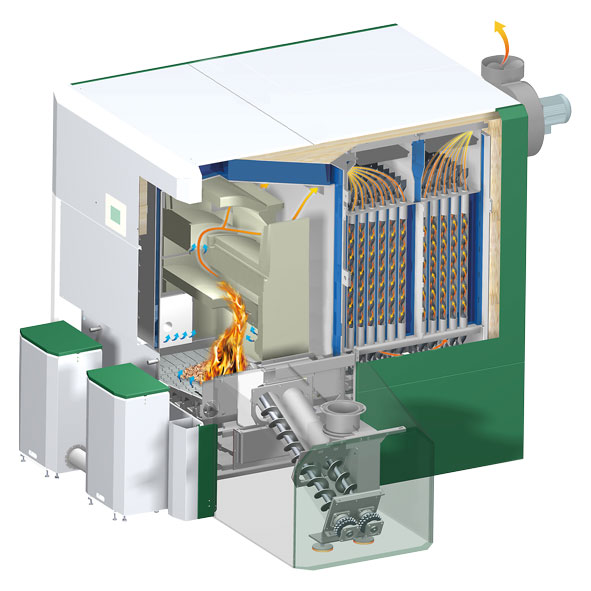

The HERZ firematic 349/401/501 kW is a biomass boiler for wood chips and wood pellets. Compact, high efficient and economical.

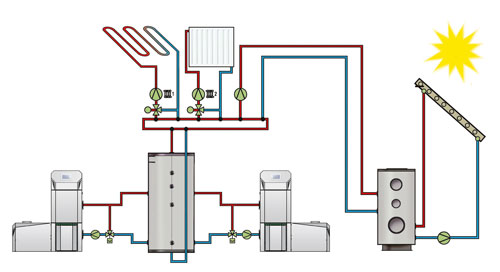

HERZ firematic can be used individually …

The great advantages of HERZ firematic 349-501 kW

- Via the two ash discharge screws the combustion and fly ash is automatically augered into the ash bins.

- For even more comfort, there is the possibility of fully automatic ash removal into an external, bigger ash container. Due to the bigger volume of ash container the intervals for empty the containers are not so often. Therefore it saves time and increases the comfort.

- Wood chips or pellets are transported from the side into the combustion chamber (with double stoker screw).

- The movement of the step grate is also a cleaning mechanism of the burning chamber. These grate elements consist of special, high-quality cast iron. Through the movement of the step- /moving grid the biomass is transported through the combustion area.

- The cleaning of the combustion chamber from burning ash is carried by an automatically tipping grid. The screw below transports the ash directly into the ash bin.

- No manual cleaning requirement.

- A built in lambda probe, which monitors continuously the flue gas values, detects fuel quality changes and ensures optimum combustion and low emission values.

- The Lambda probe controls the primary and secondary air supply ensuring complete combustion, even in partial load operation.

- The results are low fuel consumption and the lowest emission values even with different fuel qualities.

- The heat exchanger surface gets cleaned automatically via the integrated turbulators (by lifting and lowering), even during heating operation and therefore kept clean without manual effort.

- A consistently high level of efficiency thanks to cleaned heat exchanger surfaces enables low fuel consumption.

- Falling ash is taken into the ash bin via an auger.