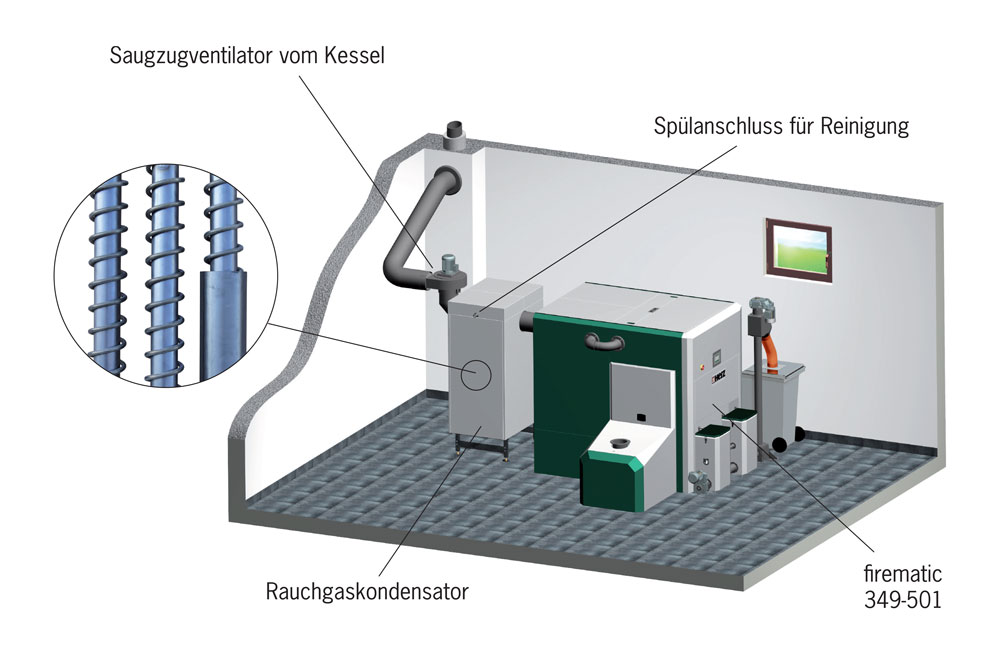

The HERZ ECOcond flue gas condenser is an additional stainless-steel heat exchanger that can be connected to the boiler’s flue pipe. The flue gas condenser consists of water-surrounded tubes through which the flue gases flow. To achieve a separation efficiency of up to 50%*, a tube-spring system is installed that sets the exhaust flow into a rotational movement. These turbulators extend the path the flue gas travels within the heat exchanger. As the gas cools (exhaust temperature below the dew point), condensate forms, which binds the dust present in the flue gas.

The turbulators are mounted on a movable linkage. A motor moves the turbulators vertically, cleaning the flue gas condenser. In addition to mechanical cleaning, water is periodically sprayed into the condenser to enhance the cleaning effect. The water connection must be provided on-site. A connection to the drainage system is also required. The rinse water and condensate can generally be discharged safely into the sewage system—although in cases of high condensate volume, some municipalities may require a neutralization system.

To guide the entire flue gas mass flow through the condenser, the boiler’s induced-draft fan is mounted at the flue gas outlet of the HERZ ECOcond. This means that no additional fan is required.

ECOcondjasmin2025-11-19T08:19:31+01:00