The BioFire 2000 Taurus is an impressive industrial version of the tried-and-tested wood chip pellet system – for reliable continuous operation and maximum efficiency.

The HERZ BioFire Taurus 2000 – individually applicable…

The great advantages of the HERZ BioFire Taurus 2000

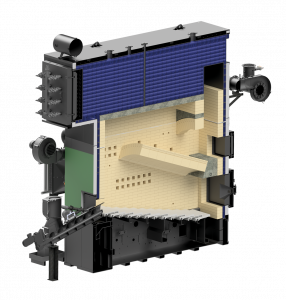

- Combustion chamber with push grate firing

Fully fireclay-lined, stoichiometrically optimised combustion chamber with primary and secondary air zones.

Hydraulically operated push grate for burning wet, ash-containing material. Fully automatic ash removal via ash slide.

» Nominal output: 2000 kW with fuel M40

» Max. water content: M50 (up to M55 with air preheating)

- Flue gas recirculation

reduces emissions and slag, automatically adjusts the combustion air and directs more heat to the heat exchanger – ideal for fuels with a high calorific value, low ash melting point and high nitrogen content.

- Automatic compressed air cleaning

Automatic compressed air cleaning of the boiler tubes significantly reduces cleaning effort and ensures longer operating times at low exhaust gas temperatures and high boiler efficiency.

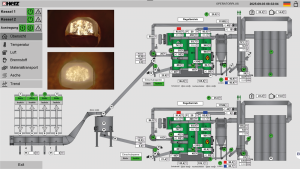

- CVP power and combustion control:

Continuously calculates current demand, controls material feed and air volumes continuously. Dynamic lambda-controlled secondary air, automatic negative pressure compensation and speed-controlled fans minimise power consumption and ensure optimum efficiency across the entire power range.

- Feeding

Feeding by means of a solid insertion screw.

- OPTIONAL: The HiLoVe system

serves as a bypass for the second heat exchanger pass and enables precise control of the exhaust gas temperature. In partial load operation, it prevents the exhaust gases from cooling down too much and condensation from forming in flue pipes and system components.

- OPTIONAL LUWA-System

The LUWA system (air preheating) preheats the combustion air, enables the efficient use of moist fuels with a water content of up to 55% and increases heat transfer, operating efficiency and sustainability.